Auto Packing Machine

Auto filling packing machine

- Packing Type: Auto filling packing machine

- Material: Stainless steel or Carbon steel

- ODM & OEM: Avalible

- Delivery time: 35 dyas

- Product description: Billicom Auto filling packing machine is widely used in chemical, pharmaceutical, food and other industries

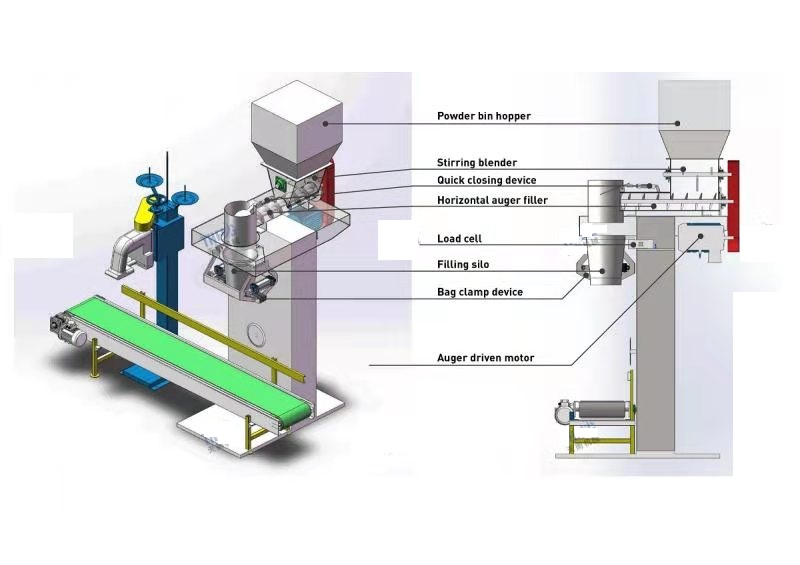

What is the Auto filling packing machine

Auto filling packing machine is especially suitable for the manual filling of small production quantities. Packing machines with low production outputs do not normally require fully automatic packing systems. Even so they still demand precise filling of their products.

Model TH-PM-50 bags filling sealing machine in chemical&food&pharmacy industry is widely used in the daily chemical industry like powder filling equipments and such like.We as a famous manufacturer moreover can design and produce the packaging machine according to the special requirements from customers.

Model

TH-PM-P-50

Filling range

20-50kg(adjustable)

Filling capacity

25*(7-10)bags/min

Power supply

1.8kw AC 380V 50/60Hz 3Phase

Air pressure

0.4-0.6Mpa

Machine weight

460kg

Machine size

240x160x280cm

Bag material

Woven bag,craft paper bags for sewing seal,PP,PET.Compound film bag,etc for heat sealing

Main Feature

►Clean bag filling

Due to product-specially chosen filling spout with all-side clamping jaws

►Space saving

Due to compact machine design

►Cost saving

Due to stable operation and low maintenance costs

►Easy handling

Due to easy and intuitive operational menu with “weight input” “weight display” “time display”

Due to clear operator guidance, easy cleaning and maintenance

►High weight accuracy: ±0.2%FS

Due to coarse and fine flow filling controlled by one frequency-change screw’s (auger’s) rotating speed

Due to the use of the Canadian General Measure or METTLER TOLEDO weighing controller and OMISEO (USA) load cell sensors

►Good product protection

Due to project-specially selected bag closure, e.g. sewing, welding or hot-melt sealing

And the Optional device:

Dust removal device. The working environment will be more hygienic if the dust removal device is added.

Working Process

Manually bag placing → Automatic weighing → Automatic filling → Automatic conveying → Automatic sealing (sewing, heating sealing) → next process

Application

This machine is especially designed for weighing filling packing 5-50kg powder of bad mobility, such as feed, fertilizers, rubber powder, PE powder, flour, etc. into open-mouth bags like plastic woven bags, woven bags, sacks, paper-plastic compound bags and barrels, cartons.

Our Services

Our Services

24 hours per day,365 days per year online service

Enquiry will be replied in 2 hours

One year warranty

OEM & ODM are available

Free spare parts for any breakdown under convincing eviden

About Us

Billicom is a group company specializing in dehydration treatment of various industrial materials, headquartered in Changzhou City, Jiangsu Province, with business in more than 20 countries and regions, selling products to customers all over the world. We are committed to innovative design and manufacturing, providing and serving high-value equipment solutions for industrial customers.

We provide customers with a wide range of industrial process solutions for material dehydration, including dryers, filtration equipment, evaporators, mixers, granulation equipment, packaging equipment, pumps, weighing equipment and heat exchangers. Our products serve global customers in chemical, food, pharmaceutical, mining, general industry and sludge treatment markets.

We are a manufacturer and after-sales service provider of highly engineered products and process solutions, which are widely used in various industrial manufacturing industries, including pumps, rotary valves, atomizers and industrial control systems. To provide high-quality, competitive price products and services to global customers.

FAQ

Q:Are you manufacturer or trading company?

A:We are group company 20 years experience professional manufacturer of drying machine,mixing machine,granulating machine.And we also have 20 years experience for exporting machines.

Q:Where is your factory located?

A:The factory located in Changzhou City,Jiangsu Province,near in Shanghai.Form Shanghai Pudong airprot to the factory is about 260Km,it need about 3 hours by car.

Q:If can make a testing in your factory?

A:Sure,our factory have Spray Dryer Machine for testing, you can take 10~50kgs raw material to our factory for testing.

Q:How Can I select the right Spray dryer Machine ?

A:We will help you choose the right type and model for Spray dryer Machine, by knowing the following information:

Liquid name and property: Solid contents(or water contents), viscosity , surface tension and PH value.

Dried powder density residual water contents allowed, particle size, and maximum temperature allowed.

Output capacity: shift time daily .

Energy that can be supplied: steam pressure, electricity properly , fuel of coal, oil and natural gas .

Control requirement: whether or not the inlet and outlet temperatures should be controlled.PLC or button type,electric component brand require.

Powder collection requirement: whether it’s necessary to use cloth bag filter and the requirement of the environment of the exhausted gas .

Other special requirements.

Contact Us

BILLICOM GROUP CO.,LTD

ADD: RM28-5,Changhong Jiayuan,Hutang Town,Wujin,Changzhou city,China

Tel : +86-519-89821556

Fax: +86-519-89821556

E-mail:info@billicomgroup.com

Whatsapp: +86-13961187595