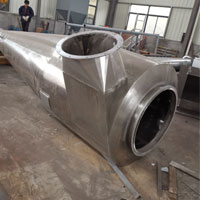

Vibrating Fluid Bed Dryer Machine

CELLULOSE Dryer

- Dryer Type:Vibrating Fluid Bed Dryer

- Material: SUS304

- ODM: Avalible

- Delivert time: 35 dyas

- Product description: Billicom CELLULOSE Dryer, Vibrating Fluid Bed Dryer is widely used in chemical, pharmaceutical, food and other industries

What is the Cellulose Dryer, Vibrating Fluid Bed Dryer

Machine Video Link: https://youtu.be/FZq4QNp9M2Q

Cellulose Dryer, Vibrating Fluid Bed Dryer Machine is a new technology developed on the basis of static fluidized bed. Mechanical vibration is added on the fluidized bed. Under the action of vibration force, the material is thrown along the horizontal fluidized bed and moves forward continuously. The hot air flows upward through the fluidized bed to exchange heat with the wet material. After the wet air is removed by the cyclone separator, it is discharged by the exhaust air 1:3. The dry material is discharged from the discharge inlet.

|

Model (ZLG) |

Length (mm) |

Width (mm) |

Total width (mm) |

Lower body height (mm) |

Upper body height (mm) |

Total height (mm) |

Weight(kg) |

|

3×0.3 |

3000 |

300 |

1350 |

900 |

430 |

1650 |

1250 |

|

4.5×0.3 |

4500 |

300 |

1350 |

900 |

430 |

1650 |

1560 |

|

4.5×0.45 |

4500 |

450 |

1550 |

950 |

430 |

1700 |

1670 |

|

4.5×0.6 |

4500 |

600 |

1650 |

950 |

430 |

1700 |

1910 |

|

6×0.45 |

6000 |

450 |

1650 |

950 |

430 |

1700 |

2100 |

|

6×0.6 |

6000 |

600 |

1700 |

500 |

1700 |

2410 |

|

|

6×0.75 |

6000 |

750 |

1850 |

1000 |

600 |

1850 |

2340 |

|

6×0.9 |

6000 |

900 |

3000 |

1000 |

600 |

1850 |

3160 |

|

7.5×0.6 |

7500 |

600 |

1850 |

1000 |

600 |

1850 |

3200 |

|

7.5×0.75 |

7500 |

750 |

2000 |

1000 |

600 |

1850 |

3600 |

|

7.5×0.9 |

7500 |

900 |

2100 |

100 |

600 |

1850 |

4140 |

|

7.5×1.2 |

7500 |

1200 |

2500 |

1150 |

800 |

2050 |

5190 |

|

Model (ZLG) |

Bed Area(㎡) |

Air inlet temp(℃) |

Air outlet temp(℃) |

Water evaporate(kg/h) |

Vibration motor |

|

|

Model |

Power (k w) |

|||||

|

3×0.3 |

0.9 |

70-140 |

40-70 |

20-35 |

ZDS31-6 |

0.8×2 |

|

4.5×0.3 |

1.35 |

70-140 |

40-70 |

35-50 |

ZDS31-6 |

0.8×2 |

|

4.5×0.45 |

2.025 |

70-140 |

40-70 |

50-70 |

ZDS32-6 |

1.1×2 |

|

4.5×0.6 |

2.7 |

70-140 |

40-70 |

70-90 |

ZDS32-6 |

1.1×2 |

|

6×0.45 |

2.7 |

70-140 |

40-70 |

80-100 |

ZDS41-6 |

1.5×2 |

|

6×0.6 |

3.6 |

70-140 |

40-70 |

100-130 |

ZDS41-6 |

1.5×2 |

|

6×0.75 |

4.5 |

70-140 |

40-70 |

120-140 |

ZDS42-6 |

2.2×2 |

|

6×0.9 |

5.4 |

70-140 |

40-70 |

140-170 |

ZDS42-6 |

2.2×2 |

|

7.5×0.6 |

4.5 |

70-140 |

40-70 |

130-150 |

ZDS42-6 |

2.2×2 |

|

7.5×0.75 |

5.625 |

70-140 |

40-70 |

150-180 |

ZDS51-6 |

3.0×2 |

|

7.5×0.9 |

6.75 |

70-140 |

40-70 |

160-210 |

ZDS51 |

3.0×2 |

|

7.5×1.2 |

9 |

70-140 |

40-70 |

200-260 |

ZDS51 |

3.0×2 |

Work Principle

The material has been feed into the machine, under the dual function of the vibration and air flow, the material move along the fluidized bed as throwing forward continuously. Hot air upward through the fluidized bed and wet materials from the heat after the exchange, after the cyclone dust emissions from dry materials from discharging from the mouth.

Vibrating Fluid Bed Dryer MAIN FEATURE

♦Materials have been heated evenly, full exchanged the heat. It is a process of large intensity of drying.

♦ The vibration motor drive has been used, with the advantages of smooth operation, easy maintenance, low noise, long life

♦ It flows stability, with no dead angle and blown through phenomenon.

♦ It is adjustable, wide adaptation. The moving speed of the bed depth and the material in the dryer can achieve stepless adjustment by the changes of the amplitude.

♦ It makes small damage to the surface of the material, can be used for the drying of the fragile materials and will not affect the work results if the particles are irregular.

♦ It uses full closed structure; effectively prevent the cross-contamination of the materials and air, clean operation environment.

♦ Materials drying time is basic equality, residence time is short, bed depth is small, usually 2 ~ 5cm.

Product Details

|

|

|

|

|

|

|

|

Vibrating Fluid Bed Dryer KEY APLLICATION

It is can be used for drying or cooling process, for the uneasily fluidized products because of large particles or irregular particles, or that require a lower fluidization rate in order to maintain the integrity of the particles and the drying of easy-to-adhesive, temperature-sensitive products and the surface water removal of the crystal water-containing materials.

♦ Petrochemical industry

I> Inorganic: borax, boric acid, glass fibers, ammonium hydrogen fluoride, potassium permanganate, sodium perborate, ammonium thiocyanate, sodium thiocyanate, cobalt sulfate, nickel sulfate, zinc sulfate heptahydrate, ammonium chloride, calcium, strontium chloride, sodium chlorate, strontium, copper sulfate pentahydrate, sodium chlorite, sodium sulfite, ammonium nitrate, calcium nitrate, sodium nitrate, potassium bromide, sodium bromide, sodium sulfate, sodium salt

II> Organics: oxalic acid, succinic acid, hydroquinone, p-nitrobenzoic acid, fumaric acid, pentaerythritol, resorcinol, catechol, calcium hypochlorite, sodium silicate, GDL, sodium gluconate, thiourea, sorbitol, dicyandiamide, iminodiacetonitrile, itaconic acid III> Fertilizer: potassium dihydrogen phosphate, calcium hydrogen phosphate, monoammonium phosphate, ammonium sulfate, magnesium sulfate heptahydrate

IV> Pesticides: Imidacloprid granules, granules glyphosate

V> Polymer: High-absorbent resin, a polystyrene resin, sodium polyacrylate

VI> Chemicals: washing powder , Chemical additives: methyl cellulose, polyacrylamide, hydroxyethyl cellulose

♦ Food and beverage industry:L-arabinose, acesulfame, erythritol, trehalose, caramel, tartaric acid, coffee, bread crumbs, mi