LW horizontal spiral discharge sedimentation centrifuge

LW horizontal spiral discharge sedimentation centrifuge

- Centrifuge Type:horizontal spiral discharge

- Material: SUS304

- ODM: Avalible

- Delivert time: 35 dyas

- Product description: Billicom's LW horizontal spiral discharge sedimentation centrifuge is widely used in chemical, pharmaceutical, food and other industries

What is the horizontal spiral discharge sedimentation centrifuge

LW series horizontal spiral discharge sedimentation centrifuge is a kind of horizontal spiral discharge and continuous operation sedimentation centrifuge, which uses centrifugal sedimentation method to separate suspension. Under full speed operation, it continuously completes the separation process of feeding, separation and discharge.

LW series horizontal spiral discharge sedimentation centrifuge has compact structure, high automation, continuous operation, stable operation, strong adaptability, large production capacity, convenient maintenance, low operation cost, low labor intensity and small floor area, which is especially suitable for the requirements of modern industrial large-scale production.

|

MODEL |

DRUM DIA mm |

DRUM LENGTH mm |

DRUM SPEED rpm |

SEPARATE FACTOR |

CAPACITYM³/h |

DRIVING MOTOR Kw |

AUXILIARY MOTOR Kw |

WEIGHT Kg |

OVERALL SIZE mm |

|

LW245×735-N |

245 |

735 |

5400 |

4000 |

0.5~4 |

7.5~11 |

3 |

900 |

1653×1200×715 |

|

LW245×980-N |

245 |

980 |

5400 |

4000 |

0.5~4 |

7.5~11 |

3 |

1000 |

1898×1200×715 |

|

LW380×1140-N |

380 |

1140 |

3500 |

2610 |

3~12 |

22~30 |

|

2400 |

2400×1820×1100 |

|

LW380×1520-N |

380 |

1520 |

3500 |

2610 |

3~12 |

22~30 |

5.5~7.5 |

2800 |

2780×1820×1100 |

|

LW450×1092-N |

450 |

1092 |

2500 |

1570 |

6~20 |

30~37 |

|

3000 |

2300×2240×1260 |

|

LW450×1350-N |

450 |

1350 |

3000 |

2260 |

6~20 |

30~37 |

7.5~11 |

3200 |

2580×1730×1260 |

|

LW450×1800-N |

450 |

1800 |

3000 |

2260 |

6~20 |

30~37 |

7.5~11 |

3800 |

3234×1730×1260 |

|

LW520×1560-N |

520 |

1560 |

2800 |

2280 |

10~35 |

37~45 |

11~15 |

4100 |

4062×1248×1429 |

|

LW520×2080-N |

520 |

2080 |

3250 |

3080 |

10~35 |

37~45 |

11~15 |

5000 |

4537×1248×1429 |

|

LW520×2080-NA |

520 |

2080 |

3000 |

2620 |

10~35 |

37~45 |

11~15 |

5000 |

4582×1248×1429 |

|

LW630×1690-N |

630 |

1690 |

2650 |

2478 |

12~45 |

55~90 |

18.5~22 |

6500 |

4200×2280×1500 |

|

LW630×2200-N |

630 |

2200 |

2650 |

2478 |

12~45 |

55~90 |

18.5~22 |

7200 |

4750×2280×1500 |

|

LW720×1800-N |

720 |

1800 |

2400 |

2320 |

30~55 |

90~110 |

22~30 |

8100 |

4528×2720×1280 |

|

LW720×2400-N |

720 |

2400 |

2400 |

2320 |

30~55 |

90~110 |

22~30 |

9200 |

5262×2720×1280 |

Work Principle

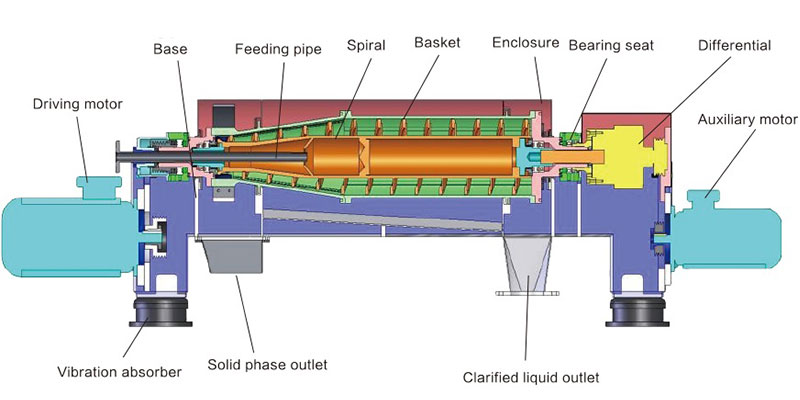

LW series horizontal screw discharge sedimentation centrifuge is mainly composed of high-speed rotating drum, discharge screw with the same rotation direction as the drum and slightly higher or lower rotation speed than the drum, differential, casing, bearing chamber, frame, motor and other parts to ensure the stable rotation speed difference between the drum and the screw.

When the suspension to be separated passes through the feed pipe of the centrifuge and enters the inner cavity of the screw conveyor, it is accelerated by the acceleration cone, It flows out from the outlet and flows to the inner wall of the drum. After entering the centrifuge drum, the high-speed rotating drum generates a strong centrifugal force, and the suspension forms a circular liquid flow in the drum. The centrifugal force makes the solid particles in the suspension with higher density than the liquid phase quickly settle to the inner wall of the drum, forming a slag ring layer. Due to the different rotation speeds of the screw and the drum, there is a relative motion (i.e. rotation speed difference) between them The solid phase deposited on the inner wall of the drum is pushed to the drying area at the small end of the drum for further dehydration by the relative movement of the screw and the drum, and then sent out through the slag outlet at the small end. The clear liquid is continuously discharged from the overflow hole at the large end of the centrifuge, and the overflow radius of the liquid phase is controlled by the regulating plate,

So as to complete the solid-liquid separation process.

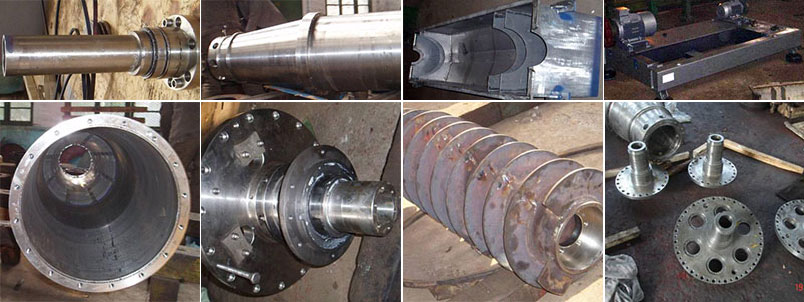

Product Details

MAIN FEATURE:

1: It can be widely used in environmental protection, chemical industry, petroleum, food, pharmaceutical and other fields requiring solid-liquid separation. It can complete solid phase dehydration, liquid phase clarification, liquid-liquid-solid, Liquid-Solid-Solid three-phase separation, particle size classification and other separation processes.

2: It has a wide range of solid particle size (0.005-5mm) and can be separated normally when the solid particle size is uneven.

3: Automatic, continuous, long-term operation, convenient maintenance, can be closed operation.

4: Single machine production capacity, compact structure, small footprint, low maintenance costs.

KEY APLLICATION:

LW horizontal spiral discharge sedimentation centrifuge is suitable for solid phase dehydration, liquid phase clarification separation, liquid-liquid-solid three-phase separation and particle size classification of various suspensions with solid particle size of 0.005-15mm, concentration of 1-45% and temperature ≤ 110 ℃. It is especially suitable for suspension separation with difficulty in filter cloth regeneration and great change in concentration and particle size. It has been widely used in solid-liquid separation of the following products:

Municipal sewage treatment, PVC resin, ammonium sulfite, sulfur paste, anthracene, barium chloride, barium carbonate, calcium carbonate, barium sulfate, strontium sulfate, calcium nitrate, calcium oxalate, lithopone, starch, diatomite, mirabilite, glutamic acid, bauxite, cellulose, soybean protein, peanut protein, fruit juice, beverage, vegetable oil, citric acid, benzoic acid, tartaric acid, blood powder, titanium dioxide It is widely used in many industrial fields, such as kaolin, calcium citrate, drilling mud, clean coal dewatering, pulverized coal dewatering, waste oil purification, distiller's grains wastewater treatment, power plant sludge, printing and dyeing sludge, paper making sludge, etc.

Our Services

24 hours per day,365 days per year online service

Enquiry will be replied in 2 hours

One year warranty

OEM & ODM are available

Free spare parts for any breakdown under convincing eviden

About Us

Billicom is a group company specializing in dehydration treatment of various industrial materials, headquartered in Changzhou City, Jiangsu Province, with business in more than 20 countries and regions, selling products to customers all over the world. We are committed to innovative design and manufacturing, providing and serving high-value equipment solutions for industrial customers.

We provide customers with a wide range of industrial process solutions for material dehydration, including dryers, filtration equipment, evaporators, mixers, granulation equipment, packaging equipment, pumps, weighing equipment and heat exchangers. Our products serve global customers in chemical, food, pharmaceutical, mining, general industry and sludge treatment markets.

We are a manufacturer and after-sales service provider of highly engineered products and process solutions, which are widely used in various industrial manufacturing industries, including pumps, rotary valves, atomizers and industrial control systems. To provide high-quality, competitive price products and services to global customers.

FAQ

Q:Are you manufacturer or trading company?

A:We are group company 20 years experience professional manufacturer of drying machine,mixing machine,granulating machine.And we also have 20 years experience for exporting machines.

Q:Where is your factory located?

A:The factory located in Changzhou City,Jiangsu Province,near in Shanghai.Form Shanghai Pudong airprot to the factory is about 260Km,it need about 3 hours by car.

Q:If can make a testing in your factory?

A:Sure,our factory have Spray Dryer Machine for testing, you can take 10~50kgs raw material to our factory for testing.

Q:How Can I select the right Spray dryer Machine ?

A:We will help you choose the right type and model for Spray dryer Machine, by knowing the following information:

Liquid name and property: Solid contents(or water contents), viscosity , surface tension and PH value.

Dried powder density residual water contents allowed, particle size, and maximum temperature allowed.

Output capacity: shift time daily .

Energy that can be supplied: steam pressure, electricity properly , fuel of coal, oil and natural gas .

Control requirement: whether or not the inlet and outlet temperatures should be controlled.PLC or button type,electric component brand require.

Powder collection requirement: whether it’s necessary to use cloth bag filter and the requirement of the environment of the exhausted gas .

Other special requirements.

Contact Us

BILLICOM GROUP CO.,LTD

ADD: RM28-5,Changhong Jiayuan,Hutang Town,Wujin,Changzhou city,China

Tel : +86-519-89821556

Fax: +86-519-89821556

E-mail:info@billicomgroup.com

Whatsapp: +86-13961187595