Spray Dryer Machine

Milk Spray Dryer

- Dryer Type: YPG Series Pressure Type Spray (Cooler) Dryer

- Material: Stainless steel or Carbon steel

- ODM & OEM: Avalible

- Delivery time: 35 dyas

- Product description: Billicom Milk Spray Dryer is widely used in chemical, pharmaceutical, food and other industries

What is the Milk Spray Dryer

Video Link:https://youtu.be/QWCA5P6SCQY

Milk Spray Dryer has a device that can function drying and granulating together. The spraying pressure, spraying flow and the size of spray nozzle of the liquid material pump can be adjusted according to the requirements and the specific size of granule balls can be achieved.

|

Item \ Model |

Unit |

50 |

100 |

150 |

200 |

300 |

500 |

1000 |

|

water evapo- |

kg |

50 |

100 |

150 |

200 |

300 |

500 |

1000 |

|

overall dimension |

mm |

1600× |

2000× |

2400× 13500 |

2800× |

3200× |

3800× |

4600× |

|

high-pressure |

mPa |

2~10 |

||||||

|

power |

KW |

8.5 |

14 |

22 |

24 |

30 |

82 |

30 |

|

inlet air |

oC |

140~350 |

||||||

|

product water |

% |

<5(可达0.5) |

||||||

|

collection rate |

% |

>97 |

||||||

|

electric heater |

KW |

75 |

120 |

150 |

temperature is lower than 200,the |

|||

|

electricity |

Mpa+KW |

0.5+54 |

0.6+90 |

0.6+108 |

according to the practical condition |

|||

|

hot air furnace |

Kcal/h |

100000 |

150000 |

200000 |

300000 |

400000 |

500000 |

1200000 |

YPG Series Pressure Type Spray (Cooler) Dryer

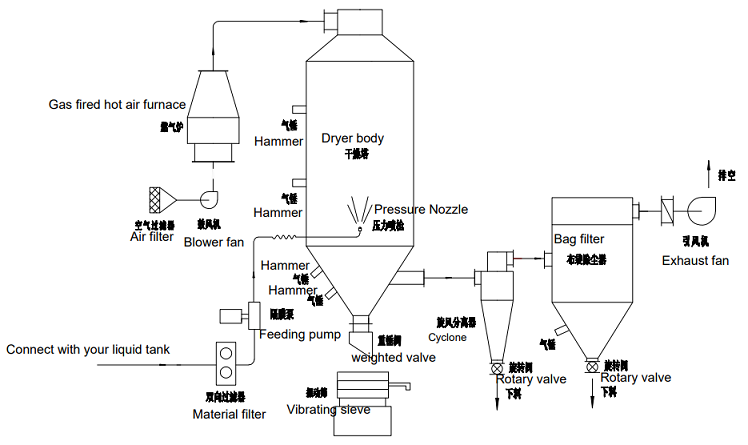

WORKING PRINCIPLEThe liquid or paste raw material is sprayed into small liquid drop by pressed sprayer draw assistance from pressure of diaphram pump, and quickly drying through amply heat exchange (10-90sec.).Most of the powder granules are collected from outlet of discharge at the bottom of the dryer. The wasted air and fine powder are separated by the cyclone, the wasted air is exhaust from draft fan, and fine powder is collected at the bottom of cyclone. There is a second grade duster equipped at the outlet; therefore, the recovery rate of the finished powder granule can be 96% to 98%.

YPG Series Pressure Type Spray (Cooler) Dryer

MAIN FEATURE

1. Rapid drying speed.The surface area of the material will be enlarged greatly when liquid raw material is atomized and 95% - 98% of water can be evaporated instantly in the hot airflow. The drying time only need to take several seconds. This dryer is especially suitable for heating sen sitive material.

2. The finished product is ball granulewith uniform size. It's fluidity and solubility are good. The quality and purity of the product is very high.

3. Depend on the characteristics of raw material, the dryer can use hot air to dry or use cool air to granulate.

4. Simple and stable operation. The control system is con venient which is easy to realize automatic operation.

Product Details

YPG Series Pressure Type Spray (Cooler) Dryer

KEY APLLICATION

Chemical industry: Sodium Fluoride (Potassium ), Alkaline Dyestuff And Pigment,Dyestuff Intermediate, Mn3o4, Compound Fertilizer, Formic Silicic Acid, Catalyst, Sulphuric Acid Agent, Amino Acid,White Carbon, and etc.

Food Industry: Fatty Milk Powder, Protein, Cocoa Milk Powder, Subsitute Milk Powder,Egg White (Yolk), Food And Plant,Oats,Chicken Juice, Coffee, Instant Dissoluble Tea ,Seasoning Meat,Protein ,Soybean,Peanut Protein, Hydrolysate, Sugar,Corn Syrup,Corn Starch,Glucose, Pectin,Malt Sugar, Sorbic Acid Potassium, and etc.

Pharmaceutical Industry: Chinese Traditional Medicines, Pesticide, Antibiotic, Medical Drinking Agent,and etc.

Plastics and Resin: AB, ABS Emulsion, Uric Acid Resin, Phenolic Aldehyde Resin, Urea-Formaldehyde Resin, Formaldehyde Resin, Polythene, Poly-Chloroprene, And etc.

Detergent: Common Washing Powder,Advanced Washing Powder,Soap Powder, Soda Ash, Emulsifier, Brightening Agent, Orthophosphoric Acid, and etc.

Ceramic: Aluminium Oxide, Ceramic Tile Material, MagnesiumOxide, Talcum, and etc. Other: Calmogastrin, Hime Chloride , Stearic Acid Agent, and etc.

Our Services

24 hours per day,365 days per year online service

Enquiry will be replied in 2 hours

One year warranty

OEM & ODM are available

Free spare parts for any breakdown under convincing eviden

About Us

Billicom is a group company specializing in dehydration treatment of various industrial materials, headquartered in Changzhou City, Jiangsu Province, with business in more than 20 countries and regions, selling products to customers all over the world. We are committed to innovative design and manufacturing, providing and serving high-value equipment solutions for industrial customers.

We provide customers with a wide range of industrial process solutions for material dehydration, including dryers, filtration equipment, evaporators, mixers, granulation equipment, packaging equipment, pumps, weighing equipment and heat exchangers. Our products serve global customers in chemical, food, pharmaceutical, mining, general industry and sludge treatment markets.

We are a manufacturer and after-sales service provider of highly engineered products and process solutions, which are widely used in various industrial manufacturing industries, including pumps, rotary valves, atomizers and industrial control systems. To provide high-quality, competitive price products and services to global customers.

FAQ

Q:Are you manufacturer or trading company?

A:We are group company 20 years experience professional manufacturer of drying machine,mixing machine,granulating machine.And we also have 20 years experience for exporting machines.

Q:Where is your factory located?

A:The factory located in Changzhou City,Jiangsu Province,near in Shanghai.Form Shanghai Pudong airprot to the factory is about 260Km,it need about 3 hours by car.

Q:If can make a testing in your factory?

A:Sure,our factory have Spray dryer Machine for testing, you can take 10~50kgs raw material to our factory for testing.

Q:How Can I select the right Spray dryer Machine ?

A:We will help you choose the right type and model for Spray dryer Machine, by knowing the following information:

Liquid name and property: Solid contents(or water contents), viscosity , surface tension and PH value.

Dried powder density residual water contents allowed, particle size, and maximum temperature allowed.

Output capacity: shift time daily .

Energy that can be supplied: steam pressure, electricity properly , fuel of coal, oil and natural gas .

Control requirement: whether or not the inlet and outlet temperatures should be controlled.PLC or button type,electric component brand require.

Powder collection requirement: whether it’s necessary to use cloth bag filter and the requirement of the environment of the exhausted gas .

Other special requirements.

Contact Us

BILLICOM GROUP CO.,LTD

ADD: RM28-5,Changhong Jiayuan,Hutang Town,Wujin,Changzhou city,China

Tel : +86-519-89821556

Fax: +86-519-89821556

E-mail:info@billicomgroup.com

Whatsapp: +86-13961187595