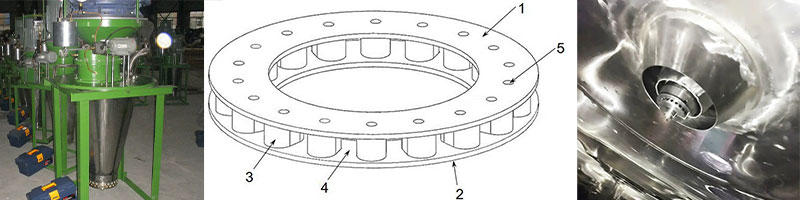

Atomizer structure of spray dryer

Atomizer structure of Spray Dryer

① Principle: a disc rotating at a high speed in the horizontal direction is used to give centrifugal force to the solution, so that it can be thrown out at a high speed to form a film, filament or droplet. Due to the friction, obstruction and tearing of the air, the tangential acceleration generated by the rotation of the spray drying disc and the radial acceleration generated by the centrifugal force result in the movement on the disc at a combined speed. Its trajectory is a spiral. After the liquid is thrown from the disc along this spiral line, It is dispersed into very small droplets, which move along the cutting diameter of the disk at an average speed. At the same time, the droplets fall by gravity. Due to the different sizes of particles sprayed. Therefore, their flying distance is different, so the particles falling at different distances form a cylinder symmetrical around the rotation axis.

② Requirements for obtaining more uniform droplets: A. reduce the vibration when the disk rotates B. keep the amount of liquid entering the disk constant in unit time C. the disk surface should be flat and smooth D. the circular velocity of the disk should not be too small, rmin=60m/s. If the emulsion (100-160m/s) is <60m/s, the spray droplets are uneven, and the spray distance seems to be mainly composed of a group of droplets and a group of fine droplets sinking near the disk, which will decrease with the increase of rotating speed.

③ Structure of centrifugal atomizer: Requirements: the wetting perimeter is long, the solution can reach high speed, the spray is uniform, the structure is solid, light, simple, no dead angle, easy to disassemble and wash, and has a high productivity.