FL Fluid Bed Granulator Machine

FL Fluid Bed Granulator Machine

- Granulator Type: Fluid Bed

- Material: Stainless steel or Carbon steel

- ODM & OEM: Avalible

- Delivery time: 35 dyas

- Product description: Billicom FL Fluid Bed Granulator Machine is widely used in chemical, pharmaceutical, food and other industries

What is the Fluid Bed Granulator Machine

Machine Video Link: https://youtu.be/a5Z3zKoWzP4

FL Series Fluid Bed Granulator Machine is the integrated use of spray and fluidization technology, the traditional process mix, granulation, drying has been accomplished once in the same equipment, it is also called "one step granulators."

Specification

FL-5

FL-15

FL-30

FL-45

FL-60

FL-90

FL-120

FL-150

FL-200

FL-300

FL-500

Volume(L)

22

45

100

155

220

300

420

530

660

1000

1500

Capacity(kg/per time)

4~6

10~20

15/45

25/65

40/80

60/120

80/160

90/200

100/300

150/450

300/300

Power of fan(kw)

3

4

5.5

7.5

11

15

18.5

18.5

22

30

37

Consume steam

0.4MPa(kg/h)

23

42

70

99

141

169

211

251

282

366

451

Consume compressed

air m3/min

1.3

0.3

0.4

0.4

0.6

0.6

0.9

0.9

0.9

1.3

1.5

Noise,db(A)

(fan is installed separately)≤75

Overall dimension(m)

1.2x

0.6x2.1

1.25x

0.9x2.1

1.6x

0.9x2.3

1.65x

1.1x2.4

1.85x

1.25x3

1.85x

1.25x3

2.2x

1.65x3.1

2.27x

1.72x3.1

2.34x

1.9x3.5

2.8x

1.9x3.8

3x

2.55x4.2

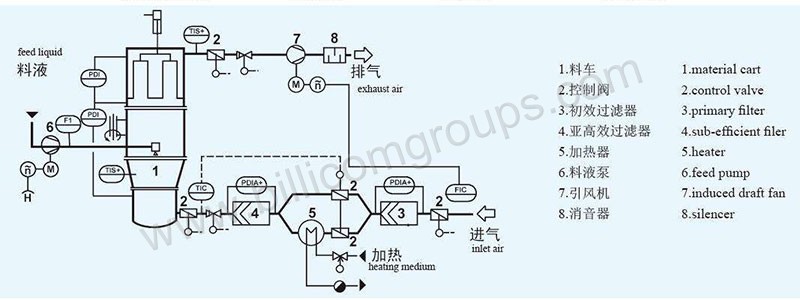

Work Principle

After purifying and heating the air in drafted by draft fan to the lower part of the drier then through the air distribution plate, making the materials powder fluidized in circular flow; Adhesive solution atomized by nozzles, the small droplet from the nozzle gathers a number of particles together as cumular spharolith. As the drying of the material, the cumularspharolith water evaporation and adhesive solution solidified. This process repeats, creating the ideal, even and porous spherical particles.

Product Details

Main Feature

1. Through the powder granulation improves liquidity and reduces dust emissions.

2. Through the powder granulation improves their dissolving performance.

3. Mixing, granulation, drying processes accomplished once in the same equipment and improving the thermal efficiency.

4. Frequency Control device is used, Hopper used inflatable seal, sealed and reliable.

5. Excellent speed controlling performance, set up pressure relief hole, safety of using.

6. No dead angle, material loading and unloading fast, easy cleaning, meeting GMP standards

Key Application

1.Medicine: Radix isatidis, Andrographolide, Allicin, Protease, Angelica, Compound Paracetamol and Amantadine Hydrochloride Capsules, Radix Astragali, Xantinol Nicotinate, Bezoar Tablet, Chlorphenamine Maleate Tablets, Qingxue-Bawei Capsule, Gentamicin, Cactus Wei Kang Capsules.

2.food and feed additives: glucosamine hydrochloride, Effect of Apramycin, TP, spectinomycin, aspartame, guitar adriamycin, Colistin of sulfuric acid, cellulose, xylanase, Metalor Streptozotocin, Thailand Miao streptozotocin, streptomycin, phytase.

Our Services

24 hours per day,365 days per year online service

Enquiry will be replied in 2 hours

One year warranty

OEM & ODM are available

Free spare parts for any breakdown under convincing eviden

About Us

Billicom is a group company specializing in dehydration treatment of various industrial materials, headquartered in Changzhou City, Jiangsu Province, with business in more than 20 countries and regions, selling products to customers all over the world. We are committed to innovative design and manufacturing, providing and serving high-value equipment solutions for industrial customers.

We provide customers with a wide range of industrial process solutions for material dehydration, including dryers, filtration equipment, evaporators, mixers, granulation equipment, packaging equipment, pumps, weighing equipment and heat exchangers. Our products serve global customers in chemical, food, pharmaceutical, mining, general industry and sludge treatment markets.

We are a manufacturer and after-sales service provider of highly engineered products and process solutions, which are widely used in various industrial manufacturing industries, including pumps, rotary valves, atomizers and industrial control systems. To provide high-quality, competitive price products and services to global customers.

FAQ

Q:Are you manufacturer or trading company?

A:We are group company 20 years experience professional manufacturer of drying machine,mixing machine,granulating machine.And we also have 20 years experience for exporting machines.

Q:Where is your factory located?

A:The factory located in Changzhou City,Jiangsu Province,near in Shanghai.Form Shanghai Pudong airprot to the factory is about 260Km,it need about 3 hours by car.

Q:If can make a testing in your factory?

A:Sure,our factory have Spray Dryer Machine for testing, you can take 10~50kgs raw material to our factory for testing.

Q:How Can I select the right Spray dryer Machine ?

A:We will help you choose the right type and model for Spray dryer Machine, by knowing the following information:

Liquid name and property: Solid contents(or water contents), viscosity , surface tension and PH value.

Dried powder density residual water contents allowed, particle size, and maximum temperature allowed.

Output capacity: shift time daily .

Energy that can be supplied: steam pressure, electricity properly , fuel of coal, oil and natural gas .

Control requirement: whether or not the inlet and outlet temperatures should be controlled.PLC or button type,electric component brand require.

Powder collection requirement: whether it’s necessary to use cloth bag filter and the requirement of the environment of the exhausted gas .

Other special requirements.

Contact Us

BILLICOM GROUP CO.,LTD

ADD: RM28-5,Changhong Jiayuan,Hutang Town,Wujin,Changzhou city,China

Tel : +86-519-89821556

Fax: +86-519-89821556

E-mail:info@billicomgroup.com

Whatsapp: +86-13961187595

0.9x2.1