PGZ Vertical Bottom Discharge Scraper Centrifuge

PGZ Vertical Bottom Discharge Scraper Centrifuges

- Centrifuge Type:Bottom Discharge Scraper

- Material: SUS304

- ODM: Avalible

- Delivert time: 35 dyas

- Product description: Billicom's PGZ Vertical Bottom Discharge Scraper Centrifuges is widely used in chemical, pharmaceutical, food and other industries

What is PGZ Vertical Bottom Discharge Scraper Centrifuges

PGZ plate type automatic bottom discharge centrifuge is a kind of high performance centrifugal filtration equipment with intermittent operation of lower discharge. It is suitable for solid-liquid separation of suspensions with high solid dispersion, moderate particle size, need washing and low liquid viscosity. It is not only suitable for small batch separation of various materials, but also suitable for mass production. It is widely used in medicine, chemical industry, light industry, food, national defense and other industrial fields.

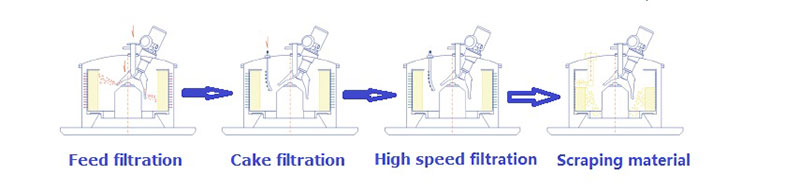

Work Principle

The bottom discharge centrifuge is the automatic filtering centrifuge. The motor drives the basket to rotate at a high speed through the belt, and the materials to be separated enter into the centrifuge basket at a high speed through the feeding system under the control of the program. Under the action of the centrifugal field, the material will be filtered through the filter media (filter cloth/screen), the liquid phase will be discharged through the liquid outlet, and the solid phase will be retained in the basket. The material detection device will detect the filling level of the material in real time. When the basket cake reaches the loading capacity specified by the machine, it stops feeding. The filter cake is then washed and dried. After the cake meets the dehydration requirements, the centrifuge reduces to the scraping speed, and the scraper removes the cake under the hydraulic (pneumatic) drive, and then the cake is discharged through the solid discharge port of the centrifuge at the lower part.

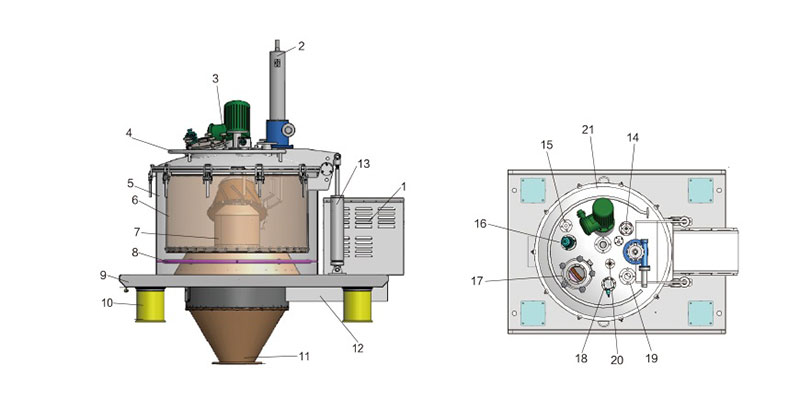

Machine Part:

Part no.

1 Motor parts 2 Scraper parts 3Inclined feeding distributor 4 CIP Upper cleaning 5 Shell 6Basket assembly 7 Transmission assembly 8 CIP Bottom cleaning 9 Base parts 10 Damping shock absorber 11 Discharge hopper 12 Belt cover 13 Balance cylinder 14 Atomizing washing pipe 15 Vent port 16 Explosion-proof lamp 17 Manhole sight glass 18 Cake layer detection device 19 Vent pipe 20 Nitrogen pipe 21Cover assembly

MAIN FEATURE:

The product has no foundation installation, and has eliminated the traditional hanging column foot, simplified the installation process, simple structure, beautiful appearance, convenient cleaning and disinfection; the absorption type isolator is adopted to prevent vibration interference on the foundation ground and surrounding equipment; all the contact elements with materials are corrosion-resistant and stainless steel; the high-efficiency washing nozzle is selected for washing, and the washing is free of blind area.

The centrifuge is driven by frequency converter and equipped with PLC programmable controller to realize soft start, stepless speed regulation, electric feedback braking and field speed regulation. It is equipped with cover opening protection, filter cake thickness detection (material controller), vibration switch protection and speed monitoring. The whole process of centrifuge feeding, washing, dehydration and unloading is realized.

TECHNICAL PARAMETER:

PARAMETER

MODEL

PGZ800-N

PGZ1000-N

PGZ1250-N

PGZ1500-N

Basket Dia (mm)

800

1000

1250

1500

Filtration Height (mm)

400

500

630

750

Basket Volume(L)

100

200

400

750

Load Capacity (kg)

125

250

500

1000

Speed(r/min)

1500

1200

1000

850

Separation factor

1008

806

700

647

Weight (kg)

2000

3000

4600

9000

Motor Power(KW)

7.5/11

11/15

22

30

Our Services

24 hours per day,365 days per year online service

Enquiry will be replied in 2 hours

One year warranty

OEM & ODM are available

Free spare parts for any breakdown under convincing eviden

About Us

Billicom is a group company specializing in dehydration treatment of various industrial materials, headquartered in Changzhou City, Jiangsu Province, with business in more than 20 countries and regions, selling products to customers all over the world. We are committed to innovative design and manufacturing, providing and serving high-value equipment solutions for industrial customers.

We provide customers with a wide range of industrial process solutions for material dehydration, including dryers, filtration equipment, evaporators, mixers, granulation equipment, packaging equipment, pumps, weighing equipment and heat exchangers. Our products serve global customers in chemical, food, pharmaceutical, mining, general industry and sludge treatment markets.

We are a manufacturer and after-sales service provider of highly engineered products and process solutions, which are widely used in various industrial manufacturing industries, including pumps, rotary valves, atomizers and industrial control systems. To provide high-quality, competitive price products and services to global customers.

FAQ

Q:Are you manufacturer or trading company?

A:We are group company 20 years experience professional manufacturer of drying machine,mixing machine,granulating machine.And we also have 20 years experience for exporting machines.

Q:Where is your factory located?

A:The factory located in Changzhou City,Jiangsu Province,near in Shanghai.Form Shanghai Pudong airprot to the factory is about 260Km,it need about 3 hours by car.

Q:If can make a testing in your factory?

A:Sure,our factory have Spray Dryer Machine for testing, you can take 10~50kgs raw material to our factory for testing.

Q:How Can I select the right Spray dryer Machine ?

A:We will help you choose the right type and model for Spray dryer Machine, by knowing the following information:

Liquid name and property: Solid contents(or water contents), viscosity , surface tension and PH value.

Dried powder density residual water contents allowed, particle size, and maximum temperature allowed.

Output capacity: shift time daily .

Energy that can be supplied: steam pressure, electricity properly , fuel of coal, oil and natural gas .

Control requirement: whether or not the inlet and outlet temperatures should be controlled.PLC or button type,electric component brand require.

Powder collection requirement: whether it’s necessary to use cloth bag filter and the requirement of the environment of the exhausted gas .

Other special requirements.

Contact Us

BILLICOM GROUP CO.,LTD

ADD: RM28-5,Changhong Jiayuan,Hutang Town,Wujin,Changzhou city,China

Tel : +86-519-89821556

Fax: +86-519-89821556

E-mail:info@billicomgroup.com

Whatsapp: +86-13961187595