PSD Vertical bag lifting Top Discharge Centrifuge

PSD Vertical bag lifting Top Discharge Centrifuge

- Centrifuge Type:Bottom Discharge Scraper

- Material: SUS304

- ODM: Avalible

- Delivert time: 35 dyas

- Product description: Billicom's PSD Vertical bag lifting Top Discharge Centrifuge is widely used in chemical, pharmaceutical, food and other industries

What is PSD Vertical bag lifting Top Discharge Centrifuge

PSD Vertical bag lifting Top Discharge Centrifuge can be used for the solid-liquid separation of suspensions containing solid particles, as well as for the solid-liquid separation of fibrous materials, such as gypsum, copper sulfate, potassium chloride, borax, dyes, pesticides, salt, monosodium glutamate, food additives, starch, sugar, chemical seasoners, antibiotics, vitamins, copper, zinc, aluminum and other minerals, metal refining, sludge treatment, and sewage treatment has been widely applied in the pharmaceutical, chemical, food, environmental protection, energy and other industries.

Work Principle

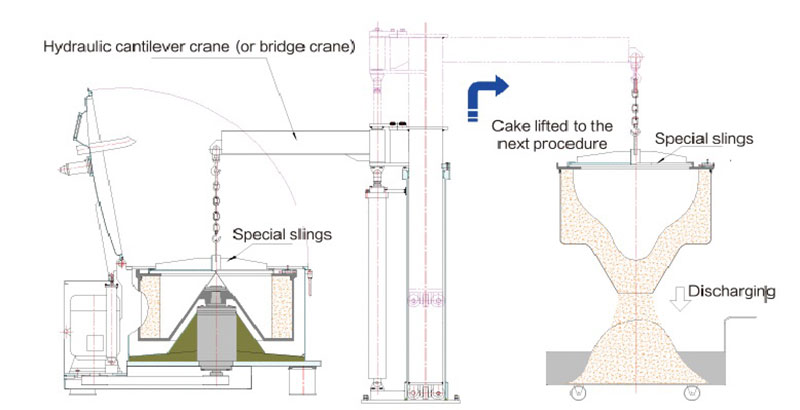

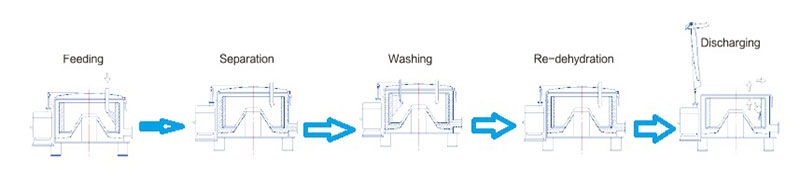

Under the action of centrifugal force, the materials reach the basket wall, where the liquid phase passes through the filtering medium covered on the basket wall and then flows through the pores on the wall to the inner wall of the enclosure, then drops off to the bottom tray and is discharged out via the liquid discharge port. While the solid matters are retained inside the basket and fully washed to complete the solid-liquid separation. After the equipment is shutdown, open the flippable cover, remove the filter bag with special lifting appliances, transfer it to the unloading area for discharging. After that, install the basket lip and filter bag back, lock the basket lip, close the flippable cover and lock it, and at this time, the next circulation can be started.

MAIN FEATURE:

Low labor intensity and high efficiency: configured with a hydraulic cantilever crane for mechanical discharge.

Grains less prone to breakage: special-purpose slings used to lift and discharge the materials as a whole.

Easy replacement of filter cloth: basket lip designed with special structure that can be disassembled fast.

Cover opening mode: hydraulic drive and mechanical drive.

Variable frequency control: stable startup and adjustable separation factor.

Stable operation: low gravity center of the equipment designed and liquid damping device adopted to attenuate vibration.

Optional configurations for the installation of cake layer control device, atomizing & washing pipe, CIP online cleaning system, explosion-proof sight glass with lamp, etc.

Multiple safety protections: nitrogen protection system, overvibration protection, cover opening protection, overload protection, electromagnetic interlocking, etc.

TECHNICAL PARAMETER:

PARAMETER

MODEL

PSD800-N

PSD1000-N

PSD1250-N

PSD1500-N

Basket Dia (mm)

800

1000

1250

1500

Filtration Height (mm)

400

500

630

750

Basket Volume(L)

100

200

400

750

Load Capacity (kg)

125

250

500

1000

Speed(r/min)

1500

1200

1000

850

Separation factor

1008

806

700

647

Weight (kg)

2000

3000

4600

9000

Motor Power(KW)

7.5/11

11/15

22

30

Our Services

24 hours per day,365 days per year online service

Enquiry will be replied in 2 hours

One year warranty

OEM & ODM are available

Free spare parts for any breakdown under convincing eviden

About Us

Billicom is a group company specializing in dehydration treatment of various industrial materials, headquartered in Changzhou City, Jiangsu Province, with business in more than 20 countries and regions, selling products to customers all over the world. We are committed to innovative design and manufacturing, providing and serving high-value equipment solutions for industrial customers.

We provide customers with a wide range of industrial process solutions for material dehydration, including dryers, filtration equipment, evaporators, mixers, granulation equipment, packaging equipment, pumps, weighing equipment and heat exchangers. Our products serve global customers in chemical, food, pharmaceutical, mining, general industry and sludge treatment markets.

We are a manufacturer and after-sales service provider of highly engineered products and process solutions, which are widely used in various industrial manufacturing industries, including pumps, rotary valves, atomizers and industrial control systems. To provide high-quality, competitive price products and services to global customers.

FAQ

Q:Are you manufacturer or trading company?

A:We are group company 20 years experience professional manufacturer of drying machine,mixing machine,granulating machine.And we also have 20 years experience for exporting machines.

Q:Where is your factory located?

A:The factory located in Changzhou City,Jiangsu Province,near in Shanghai.Form Shanghai Pudong airprot to the factory is about 260Km,it need about 3 hours by car.

Q:If can make a testing in your factory?

A:Sure,our factory have Spray Dryer Machine for testing, you can take 10~50kgs raw material to our factory for testing.

Q:How Can I select the right Spray dryer Machine ?

A:We will help you choose the right type and model for Spray dryer Machine, by knowing the following information:

Liquid name and property: Solid contents(or water contents), viscosity , surface tension and PH value.

Dried powder density residual water contents allowed, particle size, and maximum temperature allowed.

Output capacity: shift time daily .

Energy that can be supplied: steam pressure, electricity properly , fuel of coal, oil and natural gas .

Control requirement: whether or not the inlet and outlet temperatures should be controlled.PLC or button type,electric component brand require.

Powder collection requirement: whether it’s necessary to use cloth bag filter and the requirement of the environment of the exhausted gas .

Other special requirements.

Contact Us

BILLICOM GROUP CO.,LTD

ADD: RM28-5,Changhong Jiayuan,Hutang Town,Wujin,Changzhou city,China

Tel : +86-519-89821556

Fax: +86-519-89821556

E-mail:info@billicomgroup.com

Whatsapp: +86-13961187595